Scour protection at Akashi Kaikyo bridge

Some years ago, when I was in Kobe I had the opportunity to visit the Akashi Kaikyo or Akashi bridge, the bridge with the longest single span in the world (2 km). While I was looking at the documented experiences of the construction, I realized that the scour at the piers and the innovation in scour protection were among the most important and most challenging tasks.

The heavy load of the superstructure (the volume of concrete cast in each foundation exceeds 200,000 m3, totally amounting to more than 1.4 million m3 as a whole) and the harsh physical conditions of the Strait such as swift tidal currents and its heavy maritime traffic in which more than 1,400 ships navigate a day, made this project a challenge for the civil engineers.

The heavy load of the superstructure (the volume of concrete cast in each foundation exceeds 200,000 m3, totally amounting to more than 1.4 million m3 as a whole) and the harsh physical conditions of the Strait such as swift tidal currents and its heavy maritime traffic in which more than 1,400 ships navigate a day, made this project a challenge for the civil engineers.

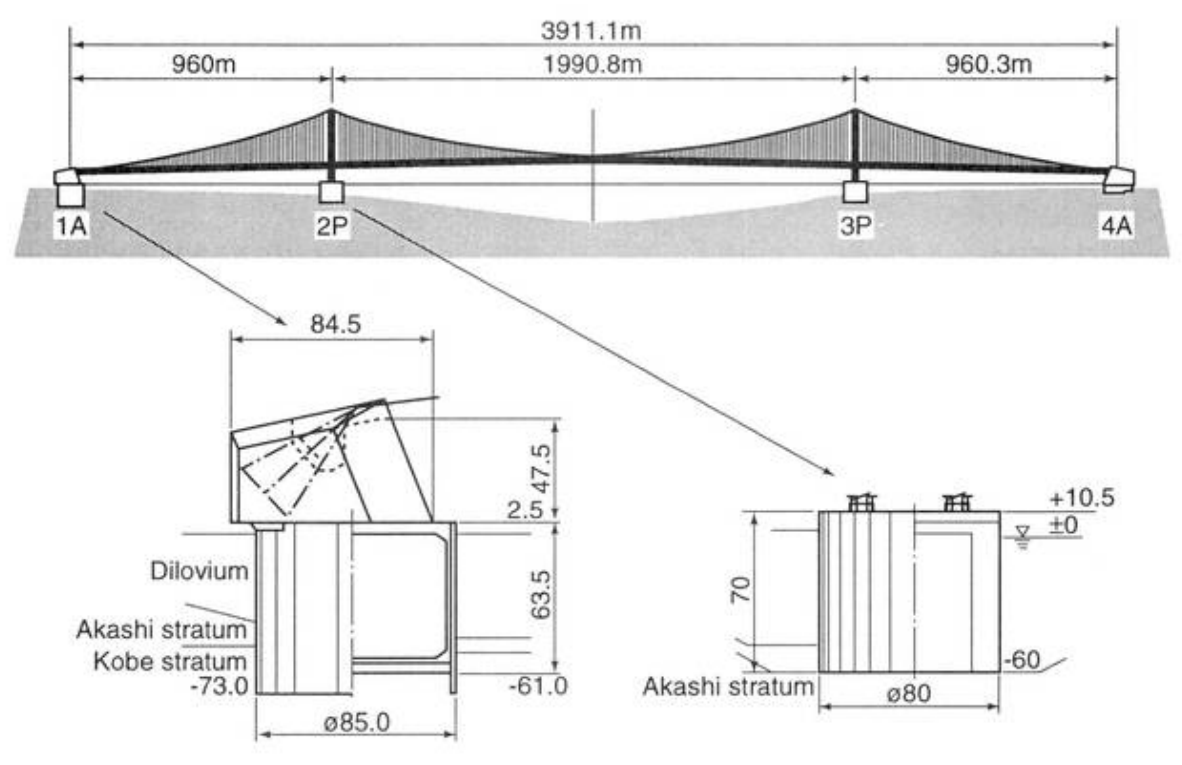

The Akashi Kaikyo Bridge as shown in Figure. 1 is a suspension bridge with a center span of 1,991 m and an overall length of 3,911 m. Foundation work conducted were for 2 anchorages at both ends of the strait and 2 tower foundations on both sides of the navigation lane. Tower foundation located in deep-water zone is a cylindrical shape foundation 80 m in diameter and 70 m high.

After excavating the seabed from 45 m to 60 m below the sea level with a grab bucket dredger, a steel caisson fabricated on a dry dock was installed. Then, scour protection composed of filter units and rip rap was executed in a range of 240 m in diameter around the caisson, and desegregating underwater concrete of 270,000 m3 was deposited in the caisson interior.

After excavating the seabed from 45 m to 60 m below the sea level with a grab bucket dredger, a steel caisson fabricated on a dry dock was installed. Then, scour protection composed of filter units and rip rap was executed in a range of 240 m in diameter around the caisson, and desegregating underwater concrete of 270,000 m3 was deposited in the caisson interior.

Figure 1. Profile of the Akashi Kaiko bridge (Source: Kashima et al., 1998)

Scour protection

The towers are located in an area of strong tidal currents where water velocity exceeds the 7 knots (about 3.6 m/s). When the caisson was installed, accelerated currents (horse shoe eddies) were generated around the caisson and scour began to advance.

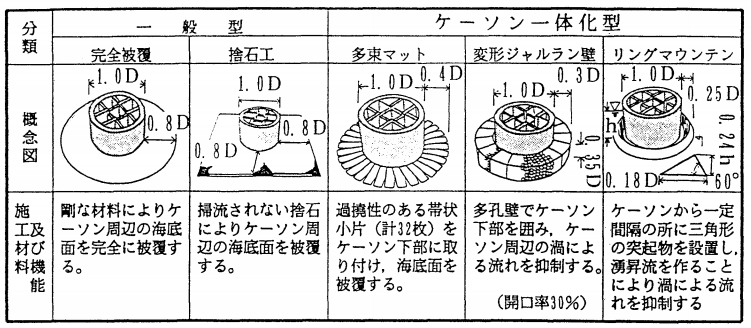

Although the peripheral of the caisson was overlaid with rip raps (1000 kg each), it was confirmed that a sucking phenomenon of ground soil through gaps of rip rap would occur around the caisson. The challenge was to find a way to prevent the scour. Several scour protection measures were analyzed, and a new practical anti-scour filter unit concept was developed (Figure 2).

The towers are located in an area of strong tidal currents where water velocity exceeds the 7 knots (about 3.6 m/s). When the caisson was installed, accelerated currents (horse shoe eddies) were generated around the caisson and scour began to advance.

Although the peripheral of the caisson was overlaid with rip raps (1000 kg each), it was confirmed that a sucking phenomenon of ground soil through gaps of rip rap would occur around the caisson. The challenge was to find a way to prevent the scour. Several scour protection measures were analyzed, and a new practical anti-scour filter unit concept was developed (Figure 2).

Figure 2. Scour protection measures considered for Akashi Kaiko (Kitagawa et al., 1991)

The selected measure included the installation of a filtering layer with a thickness of 2 m in a range of 10 m around the caisson. Then, the filter was covered with rip raps of 8 m thick. The filter unit consisted in a netbag weighing 1 metric ton and filled with crushing stones with diameters between 30 mm and 150 mm. Also, a surrounding area of 240 m was covered with rip rap. Then, a continued monitoring/investigation continued for the next 7 years.

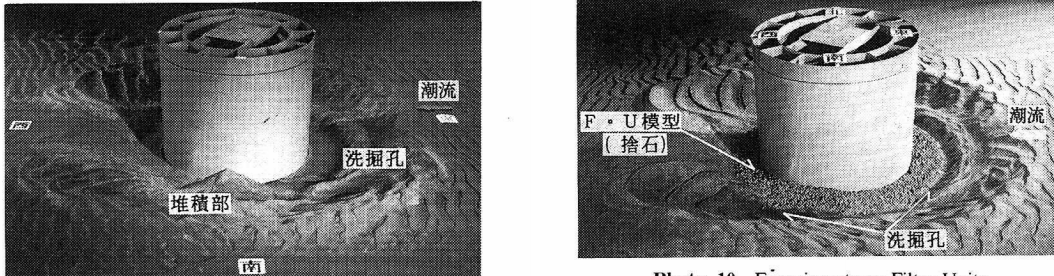

After the 7 years period, it was found that scour occurred at the out-most peripheral, but is currently stabilized. Figure 3 shows the caisson without the protection and with the protection.

After the 7 years period, it was found that scour occurred at the out-most peripheral, but is currently stabilized. Figure 3 shows the caisson without the protection and with the protection.

No comments

Post a Comment